Compressing tablets is a demanding task, depending on the composition of their ingredients and shape. From time to time it is necessary to polish the tools, as the compressed, abrasive powder reacts with the tool surface and roughen it. The roughness of the pressing surfaces is reduced by the polishing. A smooth pressing surface reduces the friction between the punch surface and the powder, which in many cases enables the press to produce more output. Furthermore, the tendency of the tablets to stick is reduced, thus guaranteeing a literally smooth pressing process. The service life of the tools can be significantly increased by polishing and the costs for tools and machine downtimes can be significantly reduced.

Even today, polishing is very often done by hand, which often leads to fluctuating polishing results. The contact pressure on the polishing disc, the processing time, the amount of polishing paste used etc. depend on the ability of the polisher when polishing by hand. As a result, it can happen that there are large differences in quality in terms of shape accuracy and surface quality within a stamp set. These differences can also lead to the tablet presses' sensitive sensors responding and interrupting production.

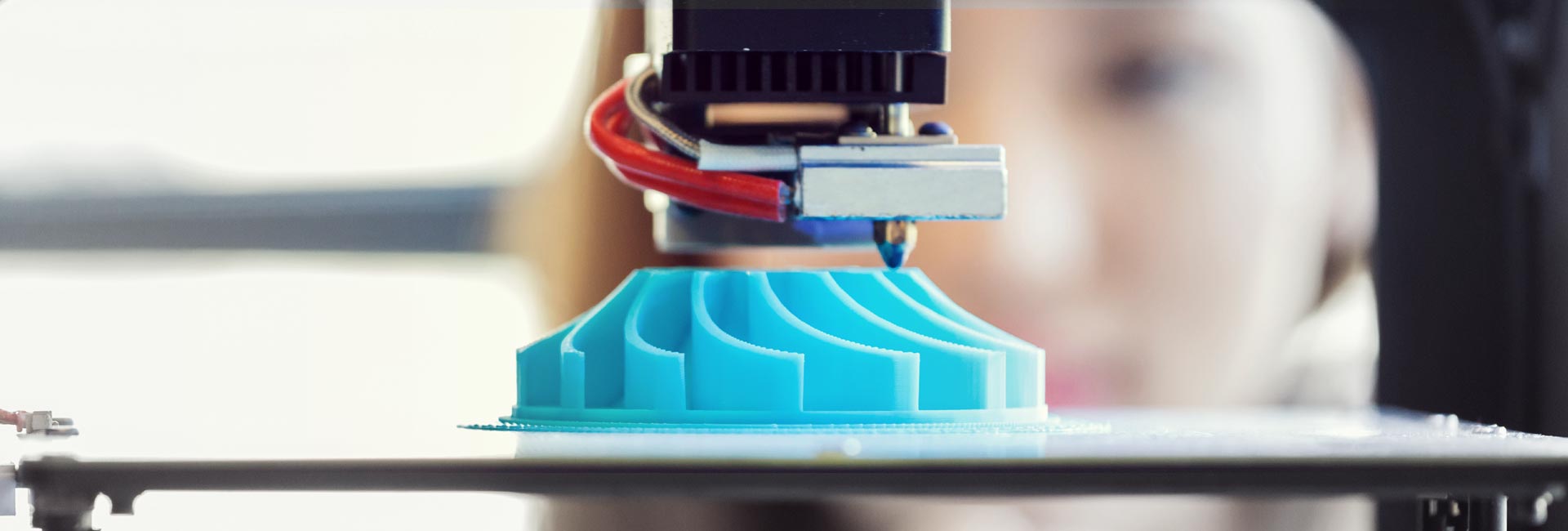

With the DF Pharma (DF-P) series, OTEC offers a fast, reliable and established polishing process. Thanks to the rotary movement of the stamp in the polishing granulate, even difficult geometries can be worked up easily and efficiently. The geometries and dimensions of the stamps are retained, as only the tips of the roughened surface are removed during the polishing process.

The design, the choice of materials and the structure of the DF-P are specially tailored to the requirements of pharmaceutical production. DF-P series machines have been in use by well-known pharmaceutical manufacturers all over the world for many years.

A polishing paste, for example, which is added to a granular plastic carrier medium, serves as a polishing agent. Only mixtures of substances that have proven themselves in pharmacy are used for the polishing process. Complex certification processes are thus greatly simplified or can be omitted entirely. Application-specific workpiece holders make a decisive contribution to perfect machining results and, in addition to optimally securing the workpieces, enable quick assembly and simple batch changes. The recordings for all common stamp formats such as EU, TSM etc. are available as standard and can be exchanged in no time at all.

In addition to the DF Pharma series, OTEC also offers machine solutions in which the loading and unloading of the system can also be fully automated using robot integration. This enables unmanned operation for many hours.