Ilg Medizintechnik GmbH

Ilg Medizintechnik GmbH company portrait

WELCOME TO ILG MEDIZINTECHNIK

FOR QUESTIONS ABOUT SURGICAL INSTRUMENTS AND MILLED PARTS WE WILL BE HAPPY TO ADVISE YOU.

MANUFACTURE OF SURGICAL INSTRUMENTS OF THE HIGHEST QUALITY

Manufacture of medical technology products, primarily surgical instruments for ENT surgery, orthopedics and spinal surgery of the highest quality. We manufacture according to national and international requirements and regulations. With the most modern CNC milling machines we also produce milled parts for medical technology as well as for aviation technology, machine and apparatus construction. We produce exclusively at our location in Durchhausen near Tuttlingen.

THE COMPANY

OVER 50 YEARS OF EXPERIENCE

With over 50 years of experience in the manufacture of surgical instruments, our customers around the world value us. The steadily increasing demands on new surgical techniques require new and modified instruments again and again. With our professionally trained employees and our most modern machine park, we are able to meet the highest customer demands. In addition to the constant expansion of our manufacturer program in the medical technology sector, we have also succeeded in opening up a further business area for our customers with high-quality CNC milled parts.

- Highest quality

- Modern CNC technology

- Quality standard ISO 13485: 2016

- 100% Made in Germany

THE HISTORY

1966 Foundation of Josef Ilg - Senior Surgical Instruments and Turned Parts

1984 Change of name to ILG Medizintechnik GmbH

1984 FDA registration

1985 Move into the newly constructed company building

1990 Opening of the new business field of CNC milling technology

2000 Extension of a production hall and expansion of the machine park

2006 Certification according to EN ISO: 13485

2012 Constantly growing family company with 14 employees

2017 Commissioning of a state-of-the-art robot system in the field of CNC milling technology

2018 Expansion of our qualifications with the upgrade audit to ISO 13485:2016

PORTFOLIO

• Manufacture of surgical instruments

• Milled parts for medical technology

• Milled parts for aerospace engineering, mechanical engineering, apparatus engineering

• Production of small and medium series

• High quality standard and quality management ISO 13485: 2016

PERFORMANCE AND SERVICE

• Competent customer support

• Direct and short communication channels

• Individual design and manufacture

• Support in the development of new surgical instruments

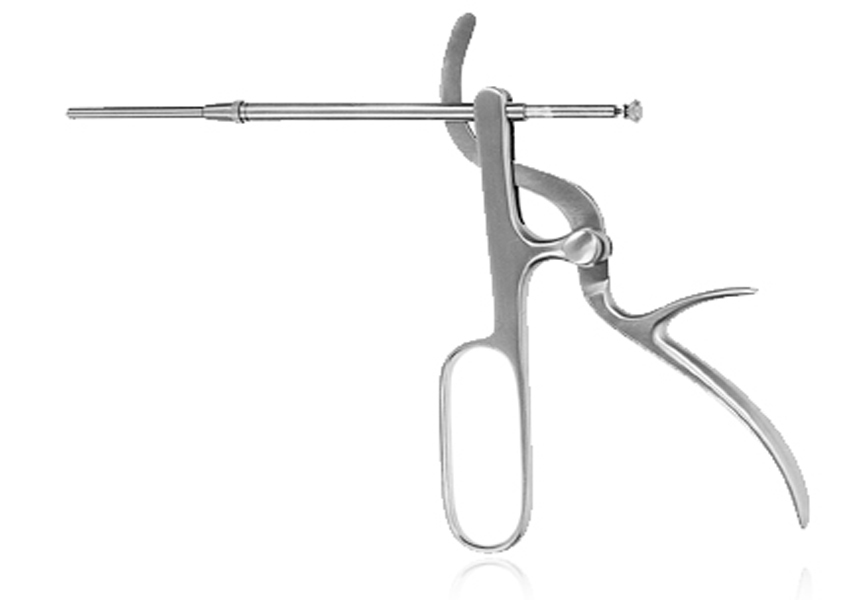

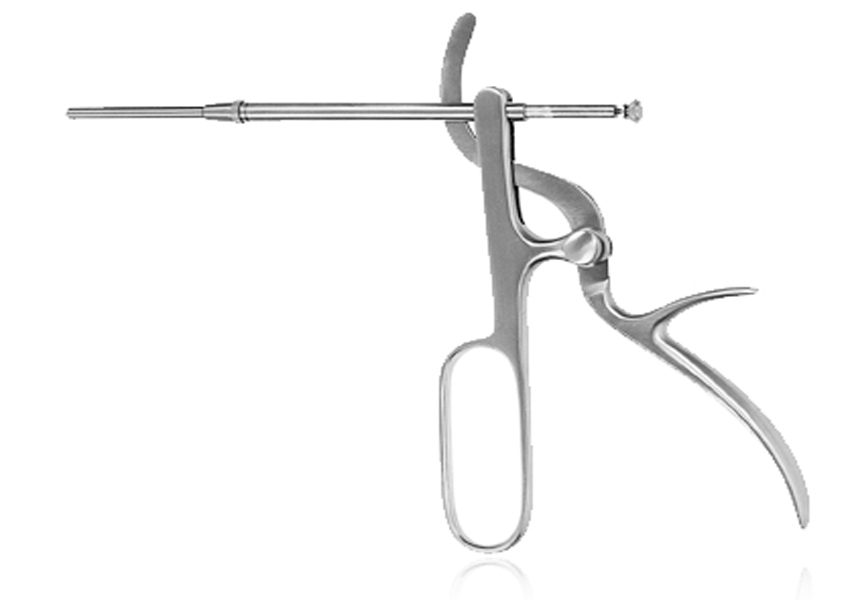

ORTHOPÄDIE / WIRBELSÄULENCHIRURGIE

In close cooperation with our customers, we manufacture a wide variety of innovative and high-quality instruments for orthopedics and spinal surgery.

These include, among others:

• Bone Holding Forceps

• Screw holding pliers

• Compressors

• Distractors

• Roll bending pliers

• Rod holding pliers

• Implant holding forceps

From development to prototype production to series production, our partners benefit from our many years of experience. Thanks to our great know-how in CNC milling, as well as great expertise in the final production of surgical instruments, we are able to manufacture even the most complicated instruments with difficult geometries for our customers.

ENT - INSTRUMENTS

Well-tried things still have their place:

In addition to the lace-ups for ear, nose and throat surgery, we manufacture a large number of suction tubes and irrigation cannulas for a wide variety of surgical applications:

• ENT

• Gynecology

• Neurosurgery

Our highly qualified employees have mastered both traditional manual work and work on technically high-quality machines.

CNC MILLED PARTS

Customers appreciate our versatility and precision. On high-quality machining centers, 3-axis and 5-axis CNC milling machines, we also manufacture robot-assisted CNC milled parts from a wide variety of materials for a wide variety of technical applications. Whether medical technology, aerospace technology, machine and apparatus engineering, you are at the right address at ILG Medizintechnik GmbH. Our construction and development department is equipped with the latest CAD technology and networked with our machining centers.

OUR QUALITY

A main component of our company philosophy is the unrestricted quality of our products as well as the trusting cooperation with our customers as well as with our suppliers. Long and good supplier relationships have meant that we prefer to purchase the necessary raw materials from regional partners. Regular intermediate controls during production as well as extensive final controls of our products ensure our high quality standard. The current certification according to ISO 13485: 2016 and a quality management system contribute to consistently good quality. With regard to the MDR, we are prepared as an extended workbench to support our customers in providing the required manufacturing documentation for the creation of the technical file.

THE CERTIFICATION

We are up to date with the latest certification. - DIN EN ISO 13485 -

CERTIFICATE ENGL. Download

FAMOUS CUSTOMERS HAVE TRUSTED US FOR 50 YEARS - WORLDWIDE!

Ilg Medizintechnik GmbH

Dorfstraße 2 I 78591 Durchhausen I Phone +49 7464 980528 I fax +49 7464 3217 I info@ilg-medizintechnik.de I www.ilg-medizintechnik.de