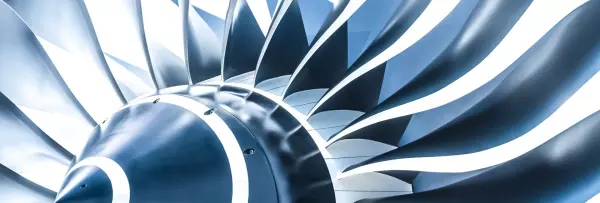

Turbine and compressor disks have mounting slots, so-called fir tree slots, in which the turbine blades are inserted. Broaching, wire EDM or milling have established themselves as manufacturing methods for these assembly slots. This creates burrs or sharp edges in the fir tree groove. For proper assembly and to avoid injuries, the edges of the fir-tree groove and those of the blade root must be free of burrs and provided with a defined radius. This is the only way to ensure proper operation of the components. In particular, the pressure surfaces where the blade root and disk are in contact during operation are subject to very tight tolerances of 10 – 20 µm. In the deburring and rounding process, there must be no shape deviations on the pressure surfaces so that the blades are in the perfect position.

In the mechanical stream finish process developed by OTEC, components such as turbine disks or turbine or compressor blades are clamped in a holder and immersed in a rotating container filled with grinding or polishing media. The workpieces can also be set in rotation or placed in the flow at defined angles.